Triple Resin Tech Simplifies High-Performance Coatings

The Architecture of Performance: A Technical Examination of a Triple Resin Coating System

Credit: studio-fi / iStock via Getty Images Plus

The industrial coatings industry has long relied on a layered approach to address the diverse demands placed on protective films. Chemical resistance, UV durability, impact tolerance and aesthetic stability are all essential attributes, and no single resin chemistry typically fulfills all these needs. In response, formulators have traditionally developed multicoat systems wherein each layer is assigned a distinct role: zinc primers for corrosion control, epoxy intermediates for barrier properties and polyurethane topcoats for gloss and UV retention.

While technically sound, this method introduces a degree of operational complexity that often proves problematic in the field. Each layer requires its own cure time, application parameters and inspection criteria. Surface contamination, mismatched recoat windows or environmental shifts such as temperature and humidity fluctuations can compromise inter-coat adhesion.

When issues occur, they are not only difficult to diagnose but also costly to resolve. As project timelines tighten and demand grows for more efficient, environmentally tolerant systems, the coatings industry faces pressure to reduce complexity without compromising technical performance.

This paper examines a formulation strategy that consolidates multiple coating functions into a single applied layer. Developed as an evolution beyond traditional stratified systems, this triple resin coating system integrates three separate chemistries, each with specific functional contributions, into one chemically unified film. The result is a coating that seeks to preserve the performance advantages of multicoat architectures while delivering a more straightforward, faster and more robust solution for field and shop-floor applications.

Formulation Strategy and Resin Components

The foundation of this approach lies in the deliberate selection and chemical compatibility of three primary resins:

A cyclic polyolefin-based polymer

A cycloaliphatic polyurethane

An aliphatic polyaspartic

Each resin contributes to a specific domain of performance, and together, they co-react to form a single crosslinked polymer network during cure.

Cyclic Polyolefin-Based Polymer

Serving as the primary barrier resin, the cyclic polyolefin-based polymer provides the dense, inert matrix necessary for chemical resistance and moisture impermeability. Unlike traditional epoxies, which often embrittle over time or under cyclic loading, this polymer retains its flexibility and integrity. Its molecular structure is characterized by tightly packed chains and minimal free volume, which translates into low water vapor transmission rates and high resistance to underfilm corrosion.

This resin also plays a mechanical role in the system. Its rigidity under strain provides structural stability, particularly in applications subject to dynamic stresses such as vibration or thermal cycling. As the foundational component of the formulation, the cyclic polyolefin contributes to both long-term barrier function and physical durability.

Cycloaliphatic Polyurethane

The second resin in the formulation is a cycloaliphatic polyurethane, chosen for its resistance to ultraviolet degradation and weathering. Derived from sterically hindered aliphatic isocyanates and UV-stable polyols, this polyurethane is chemically engineered to avoid the common pitfalls of aromatic variants, which degrade quickly under UV exposure.

The cycloaliphatic structure provides shielding for sensitive chemical bonds, limiting photolytic and oxidative reactions. This ensures long-term color and gloss retention, even in high-sunlight environments. In addition to aesthetic performance, the resin contributes thermal stability and surface hardness, further rounding out the formulation’s physical property profile.

Aliphatic Polyaspartic Resin

Completing the resin triad is an aliphatic polyaspartic resin, which is formed by reacting a polyaspartic ester with an aliphatic isocyanate. This component offers several key benefits. First, it enables a rapid cure profile, reducing overall project timelines. Second, it is highly tolerant to humidity and temperature variations during application. These properties are particularly useful in real-world environments where conditions are rarely ideal.

The polyaspartic resin also contributes to film build and pot life control, helping the system maintain a workable consistency and ensuring even coverage. Its fast-reacting nature supports same-day return-to-service timelines and facilitates use in both field-applied and factory-controlled settings.

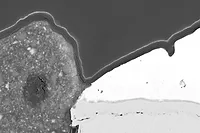

FIGURE 1 | Comparison of conventional multilayer coating systems with a single-coat triple resin formulation. The illustration demonstrates how three distinct resin chemistries, each contributing specific functional properties, are integrated into a unified, co-curing film. This configuration retains the performance benefits of traditional layered systems while simplifying application.

Resin Integration Through Co-Curing

While each resin in the system offers unique attributes, the formulation’s performance depends on more than just its individual properties. Central to the system’s effectiveness is its co-curing behavior. Unlike traditional multicoat systems, where each resin is applied and cured in isolation, the triple resin formulation is designed for simultaneous chemical reactions.

This co-curing strategy addresses several critical challenges. First, it prevents phase separation, a common issue when combining chemically dissimilar polymers. The resins in this system are selected not only for their function but also for their compatibility in terms of reactivity, polarity and molecular weight distribution. Second, simultaneous cure minimizes differential shrinkage and stress accumulation within the film. These stresses, if unmitigated, can lead to cracking or delamination over time.

The result is a coating with a uniform modulus profile across the film thickness. This uniformity enhances both mechanical toughness and resistance to environmental degradation.

Furthermore, the system achieves a high crosslink density, improving chemical resistance and moisture impermeability. The balance of hardness and flexibility achieved through co-curing is especially significant, as most conventional coatings tend to favor one of these properties at the expense of the other.

Application and Performance Considerations

From a practical standpoint, this triple resin coating system is designed to perform in varied and unpredictable environments. Its moisture-tolerant cure behavior, primarily driven by the polyaspartic component, allows for application under high-humidity or low-temperature conditions without introducing common defects such as amine blush or incomplete film coalescence.

The barrier properties of the cyclic polyolefin base bolster the formulation’s chemical resistance. At the same time, the cycloaliphatic polyurethane ensures surface durability in the presence of UV light, cleaning agents and temperature fluctuations. In combination, the three resins contribute to a versatile performance profile that addresses the full range of chemical, mechanical and aesthetic challenges commonly encountered in protective coatings.

In addition, the single-coat approach simplifies logistics. It reduces labor requirements, eliminates inter-coat inspection steps and shortens turnaround time. This streamlined process is particularly advantageous in fast-paced project environments or settings where consistent environmental control is difficult.

Conclusion and Future Work

The triple resin coating system discussed in this article represents a departure from traditional multilayered coating strategies. By integrating three distinct resin chemistries into a single, co-curing matrix, the system achieves multidomain performance without requiring multiple application steps. It offers a practical solution to the longstanding tension between high-performance and field-friendly applications.

This formulation approach demonstrates that it is possible to design coatings that meet or exceed the protective benchmarks of traditional systems while offering greater flexibility in application and reduced potential for field failure. The synergy of the resins within a co-reactive system enables balanced properties: mechanical strength, UV stability, chemical resistance and fast cure, without relying on layering or staged reactivity.

Further validation is currently underway through comparative testing against conventional coating systems. This testing includes:

Corrosion resistance (ISO 12944-6)

Flexibility (ASTM D522)

Impact resistance (ASTM D5420)

Gloss and color retention (QUV accelerated weathering)

Adhesion performance under variable conditions (ASTM D3359, ASTM D4541)

These studies are expected to provide quantitative benchmarks for evaluating the efficacy and potential adoption of unified resin coating systems in industrial applications.

For technical inquiries or collaboration opportunities, readers are encouraged to contact the technical services team at Advanced Polymer Coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!